Dual Inlet®

In order to maintain their performance, conventional Bottle Top Dispensers are always rinsed once they have been used with strong or hazardous reagents. For this, the instrument is dismounted from the reagent bottle and then put onto another bottle containing distilled water. Once it has been rinsed, it is remounted back onto the reagent bottle.

The mounting and dismounting of conventional Bottle Top Dispensers is so tedious that in practical usage, most laboratory personnel do not comply with it. This directly results in reduction of the life of the instrument. Once all the reagent has been used up, the same activity has to be done during bottle refilling.

Spring Metal Reactivity

Depending on the application, the spring in the outlet valve is either made of Platinum Iridium or Tantalum. Platinum Iridium is not suitable for Hydrogen Peroxide whereas Tantalum has limitations with Sodium Hydroxide. Because of this spring metal reactivity, the user has to procure different kinds of Bottle Top Dispensers for different applications which just adds confusion and proves to be an expensive proposition.

Chemical Deposition

The spring also offers a surface for deposition of chemicals. This results in a piston jam, thereby compelling the user to repeatedly clean the valve, or replace it altogether.

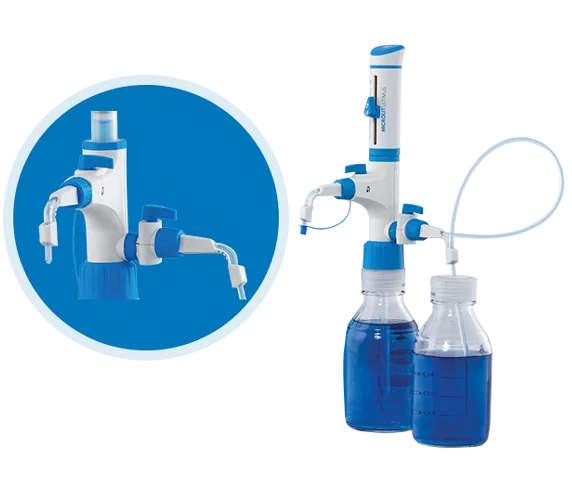

MICROLIT’s Expert Technology Solution – Dual Inlet®

It prevents cross contamination and lets MICROLIT ULTIMUS, our advanced Bottle Top Dispenser, offer four modes of liquid handling – rinsing, dilution, refilling, purging – without dismounting. This award-winning technology, patented in India, the EU and the US, also substantially enhances the chemical compatibility and life of the instrument..