Exploring Peristaltic Pumps, Their Functionality and Diverse Applications

- February 19, 2025

- ENQUIRE NOW

In the world of fluid management, precise control and efficient transfer of liquids and slurries are paramount, especially in industries that require high standards of hygiene, accuracy, and minimal contamination. Among various pump types used in these sectors, peristaltic pumps stand out due to their unique mechanism of action and diverse range of applications. In this blog, we will explore the functionality of peristaltic pumps, their design, and their use across different industries.

What is a Peristaltic Pump?

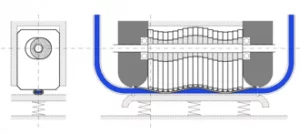

A peristaltic pump, often referred to as a hose or roller pump, is a type of positive displacement pump that uses a unique mechanism to move fluids. The working principle of a peristaltic pump is based on the peristalsis process—an involuntary constriction and relaxation of muscles, as seen in the human digestive system. In the pump, rollers or shoes move along the surface of a flexible tube or hose, compressing it and creating a cavity that traps liquid. As the rollers move along the tube, the liquid is pushed forward in discrete amounts, ensuring accurate flow and minimal shear forces on the fluid.

Functionality of Peristaltic Pumps

The primary advantage of peristaltic pumps lies in their simple yet effective mechanism. Here’s a step-by-step breakdown of how these pumps work:

- Compression of the Tube: The pump contains a rotating rotor with rollers or shoes that press against the tube. This compression squeezes the liquid within the tube, creating a seal behind it.

- Trapping the Fluid: As the rollers move along the tube, they progressively push the trapped liquid forward. The movement of the rollers creates discrete pockets of fluid, which are moved through the pump with minimal turbulence.

- Flow Control: Since the liquid is pumped in separate, measurable volumes, peristaltic pumps offer precise flow control. The rate of flow can be adjusted by varying the speed of the rotor or the size of the tubing.

- Minimal Contact with Fluid: One of the significant benefits of a peristaltic pump is that the fluid only comes into contact with the inner walls of the tubing, not with any mechanical components like gears or pistons. This reduces the risk of contamination, making peristaltic pumps ideal for applications that require sterile conditions.

- Self-Priming Capability: Peristaltic pumps are self-priming, meaning they can begin pumping without the need for additional assistance, such as filling the pump with liquid.

Key Features of Peristaltic Pumps

-

Peristaltic pump in motion Variable Flow Rate: Flow rates are highly customizable, and can be adjusted by modifying the speed of the motor or selecting different tubing sizes.

- Accurate Fluid Transfer: The pump’s positive displacement action ensures that a specific volume of liquid is moved with each cycle, making it ideal for applications requiring precision.

- Non-Contaminating: Since the fluid is only in contact with the tubing, there is little risk of contamination from the pump’s mechanical components.

- Handling Viscous Fluids: Peristaltic pumps are capable of handling thick and viscous liquids, making them useful in applications where other pump types might struggle.

- Chemical Compatibility: The choice of tubing materials (e.g., silicone, PVC, rubber) allows the pump to handle a wide variety of chemicals and fluids.

Applications of Peristaltic Pumps

Peristaltic pumps are incredibly versatile and are used across numerous industries where accurate, reliable fluid transfer is necessary. Below are some key sectors where peristaltic pumps excel:

-

Pharmaceutical and Biotechnology Industries

In the pharmaceutical and biotechnology industries, sterility and accuracy are non-negotiable. Peristaltic pumps play a critical role in these sectors due to their ability to transfer fluids without contaminating them.

- Sterile Fluid Transfer: Peristaltic pumps are commonly used for transferring sterile solutions, such as intravenous (IV) fluids, in medical devices.

- Reagent Dispensing: In laboratories, these pumps are used for dispensing small, precise amounts of reagents or chemicals in experiments.

- Cell Culture Media: They are employed in bioreactors for adding culture media to growing cells, ensuring no contamination with the pump mechanism.

-

Food and Beverage Industry

The food and beverage sector demands strict hygiene standards and the careful handling of ingredients. Peristaltic pumps are often the go-to solution due to their hygienic design and ability to handle a wide range of liquids.

- Juices and Dairy Products: Peristaltic pumps are used for transferring juices, milk, and other beverages, as the gentle pumping action ensures that these delicate fluids are not degraded.

- Flavor and Additive Dispensing: They are used for adding flavorings, preservatives, or sweeteners to liquids without contaminating them.

- Food Processing: These pumps are also used for transferring sauces, purees, and other viscous foods in production lines.

-

Water Treatment and Environmental Applications

In water treatment, peristaltic pumps are used to move a wide range of liquids, including wastewater, chemicals, and cleaning agents.

- Chemical Dosing: Peristaltic pumps are widely used in chemical dosing systems for precise addition of chemicals such as chlorine or coagulants in water treatment plants.

- Desalination: They are employed in desalination processes, where controlled fluid transfer is crucial for separating salt from seawater.

-

Chemical and Petrochemical Industries

Peristaltic pumps are particularly useful in the chemical and petrochemical industries, where the fluids being handled can be highly corrosive, viscous, or hazardous.

- Acids and Solvents: These pumps are ideal for transferring aggressive fluids, such as acids, solvents, and oils, as the liquid never comes into contact with the pump’s mechanical components.

- High Viscosity Fluids: Peristaltic pumps can efficiently handle viscous fluids like paints, resins, and adhesives, making them indispensable in various chemical processing applications.

-

Mining and Metallurgy

In the mining industry, peristaltic pumps are used for transferring abrasive slurries and other materials that are difficult to pump with other types of pumps.

- Slurry Handling: They can transport thick slurries made up of water and mineral ores, with the tube material being resistant to abrasion.

- pH Control: Peristaltic pumps can be used to precisely add chemicals to control the pH levels in mineral processing.

-

Medical Devices and Laboratory Applications

Beyond the pharmaceutical industry, peristaltic pumps are found in various medical devices and laboratory equipment.

- Infusion Systems: In hospitals, they are used in infusion pumps for controlled delivery of drugs and fluids to patients.

- Laboratory Fluid Handling: These pumps are used for handling small volumes of chemicals and biological fluids in laboratory settings.

Conclusion

Peristaltic pumps are indispensable tools across various industries due to their ability to transfer fluids with precision, accuracy, and minimal contamination. Microlit’s range of peristaltic pumps offers flexible, high-quality solutions for a wide variety of applications, from laboratory research to large-scale industrial processes. With the versatility, reliability, and hygienic nature of these pumps, Microlit continues to be at the forefront of providing fluid handling solutions that meet the needs of diverse industries around the world. Whether for pharmaceutical, food processing, water treatment, or chemical dosing, peristaltic pumps from Microlit ensure optimal performance and superior results. Explore us at https://www.microlit.com/product-category/peristaltic-pump/